Just how resilient is a galvanized finish? In the world of dump trailers, durability is not just a desirable trait, but an absolute necessity. A sturdy build is paramount to ensure your trailer can endure the rigors of heavy loads, challenging terrains, and inclement weather conditions. One proven method to attain this remarkable resilience and longevity is by employing a galvanized steel finish. In this insightful article, we will delve into the intricacies of the hot-dip galvanizing process, explore the principles of cathodic protection and sacrificial anodes, and juxtapose the hardness and durability of galvanized steel against the powder-coat paint process.

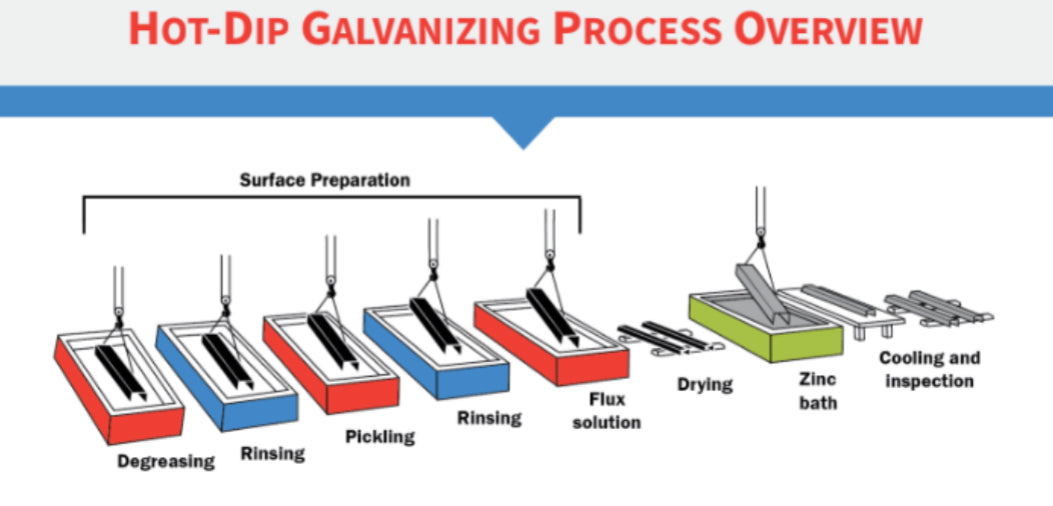

The Hot-Dip Galvanizing Process: This is a prevalent technique for safeguarding steel from corrosion. It entails submerging the steel trailer into a vat of molten zinc, which subsequently forms a metallurgical bond with the steel. This zinc coating serves as a protective shield, effectively insulating the steel from corrosive elements such as moisture, salt, and chemicals.

Drawing credit: American Galvanizing Association

What is the mechanism behind galvanization that safeguards steel from corrosion? Galvanized steel employs a principle termed as cathodic protection, a strategy designed to shield against the corrosive effects. This principle operates on the basis of an electrochemical process that inhibits the degradation of metals. Specifically, the zinc layer enveloping the galvanized steel serves as a sacrificial anode. This implies that it willingly submits to corrosion in place of the steel. This act of sacrificial corrosion guarantees the steel's protection, even in instances where the zinc coating might be damaged or compromised.

Drawing credit: American Galvanizing Association

The superior hardness and durability of a galvanized steel finish on a dump trailer is a key advantage. The hot-dip galvanizing process forms a thick, chemically bonded zinc coating that resists abrasion, impact, and scratches. This robust layer offers enduring protection against corrosion, significantly prolonging the trailer's lifespan.

How does it outperform traditional painting? While powder-coat paint is a common method for steel protection, it often falls short in durability compared to galvanized steel. Powder coating depends on a painted surface, which is susceptible to chipping, cracking, and fading over time. Even minor imperfections in the paint can expose the underlying steel to corrosion. In a dump trailer, hinges and other moving parts can quickly lose their paint, revealing signs of rust within days, depending on the climate. In contrast, a galvanized steel finish provides a more resilient and reliable barrier against corrosion, ensuring a longer lifespan for the dump trailer.

Dump trailers lead a demanding life, making toughness and durability essential for long-term performance. A galvanized steel finish provides exceptional corrosion protection, thanks to the hot-dip galvanizing process, cathodic protection, and sacrificial anodes. The hardness and longevity of galvanized steel outshine the durability of the powder-coat paint process, ensuring your dump trailer can withstand the harshest conditions and deliver reliable service for years to come.

At Pono Trailers, we are committed to offering a full range of galvanized trailers to the market. Our aim is to provide our customers and friends with the highest quality, longest-lasting trailers possible. By choosing a Pono galvanized dump trailer, you are investing in a reliable and durable solution that delivers the toughness needed for our beautiful Hawaiian island home.

Remember, whether you're hauling heavy loads or navigating challenging terrain, a galvanized dump trailer will stand strong, ensuring your business operations run smoothly with peace of mind.